Linear guideways are used to convert rotational movement into linear movement, enabling equipment to run at high loads and high speeds. This paper will consider the construction characteristics and typical application examples of five different types of linear guide rails, allowing you to select the right guideway system for your individual needs.

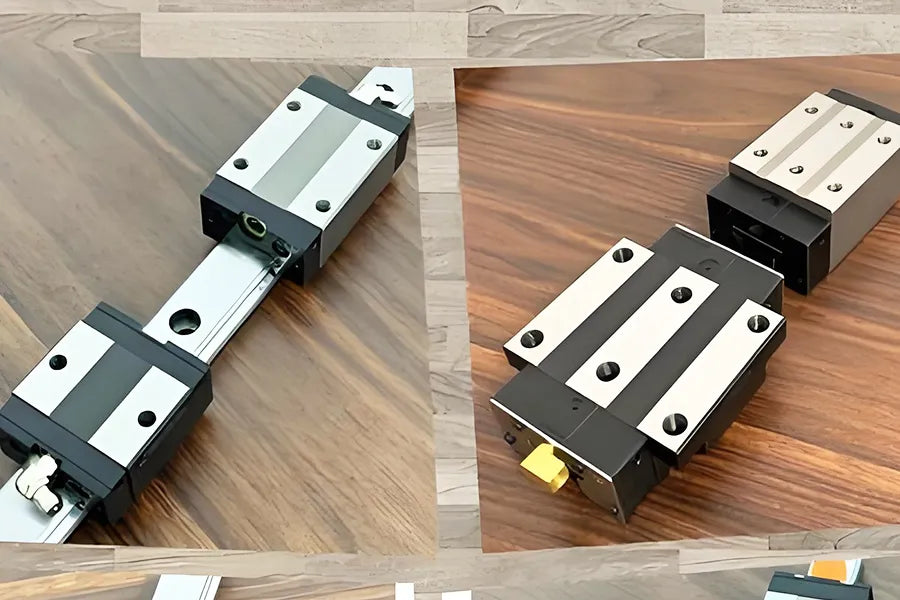

1. LMG Series

LMG is a heavy load and high-precision standard guideway and is one of the most versatile series of linear guide rails, finding application in CNC machine tools, automated production lines, laser machines and testing equipment.

1.1 Features

Its ball recirculation construction gives a very low friction co-efficient. Its square guide block construction gives a large amount of torsional rigidity. It gives uniform loads in all four directions (uniform load in the vertical and horizontal direction).

1.2 Advantages

High rigidity and high precision. Smooth running and low noise. Easy maintenance and long life.

1.3 Typical Applications

CNC engraving machines, laser welding machines, semiconductor testing machinery, automatic dispensing systems, etc.

2. LMGQ Series

The LMGQ linear guide rail is a silent linear guide rail. By optimizing the ball circulation path and slider structure, it achieves smoother, quieter operation.

2.1 Features

- An optimized ball circulation system effectively reduces metal-to-metal collision noise.

- Slider-to-rail contact is smoother, minimizing operating resistance.

- Equipped with sealed, dust-proof end caps for extended service life.

2.2 Advantages

- Quiet Operation: Noise is reduced by over 20% compared to conventional models.

- High Smoothness: Smooth operation with no noticeable vibration.

- Long-Life Design: Lubrication is maintained longer, extending maintenance intervals.

2.3 Typical Applications

Automated testing equipment, laboratory instruments, medical equipment, automated assembly lines, and precision handling systems for 3C electronics.

3. LMR Series

Miniature Design, Using Compact Space. The linear roller guide backwards is a combination of a flat guide and linear roller guide, where rollers on the parallel rails replace steel balls to carry the machine parts.

3.1 Features

It has a line-to-surfaces contact therefore it is able to give greater rigidity and greater loads than the ball type guides of the same dimension.

The slider and guide rail consists of a compact action as easy of location.

3.2 Advantages

Great area of contact, large load capacity and high sensibility. If we look from the back to the machine bed, the brackets and rollers are located on the upper side and the side faces of the plain guide. To effect the high precision desired, a wedge is located between the working part of the machine tool and the inner surface of the brackets, whereby the preload is directed on to the side surfaces of the bracket.

3.3 Typical Applications

Medical appliances, electrical assembling machines, optical testing equipment. and semiconductor handling. devices.

4. LMN Series

Low Assembly Design and less fitted space. The LMN linear guide rail is a low assembled guide, which reduces the assembly height and slide length, to be applied where there is little space.

4.1 Features

The low height slide makes it just the thing to be built in equipment which has a limited space.

The recirculation of balls have an optimised system which reduces the amount of friction.

4.2 Advantages

Low centre of gravity structure which gives a stable running.

These are suitable for systems needing it to be light weight and low inertia.

4.3 Typical Applications

Laser marking machines, automatic measurement, instruments, small CNC machine tools and sensor transfer platforms.

5. LMNW Series

Wider, Low-Assembly Design for Greater Stability. The LMNW reduces assembly height while increasing the guideway width, resulting in a higher permissible torque. Structural

5.1 Features

- The widened slide design can withstand greater torque.

- The low installation height makes the overall equipment structure more compact.

5.2 Advantages

- High precision, high load capacity, and low vibration.

- Commonly used for structures with small spaces and high torque.

5.3 Typical Applications

Precision laser cutting machines, automated welding platforms, inspection systems, and robotic linear modules.

6. How to Select the Proper Linear Guide Rail?

Give considerations, call-forwards for the selection of guide rails.

- Projection and direction of the carried load: For large dimensions in loads LMGQ or LMNW should be chosen.

- Space available for the equipment: For compact arrangements LMN or LMR should be considered.

- Accuracy and rate of speed of motion: For high accuracy in motion, as in laser operation, and in measuring apparatuses, LMG or LMR should be used.

- Natural (environmental) conditions: For damp or corrosive environments LMR guide rails of stainless steel should be specified.

Summary

Linear guide rails constitute the extremely Active-Parts of our present day happenings for all cases of true linear movement. Their performances determine directly the perfect working of the best machinery in stability and in life. When the proper guide rail is selected they not only improve the readings of the machinery materially, but also reduce the cost of maintenance and improve the entire output of production in tonnage.