Motor technology plays a central role in modern automation and precision control. With the continuous advancement of manufacturing, robotics, and intelligent devices, traditional rotary motors are no longer able to meet increasingly complex motion requirements. This is why dual axis linear stepper motors have emerged. They not only provide precise linear motion but also enable synchronized or independent control in two independent directions, making them an efficient and flexible motion solution.

1. What is a Dual Axis Linear Stepper Motor?

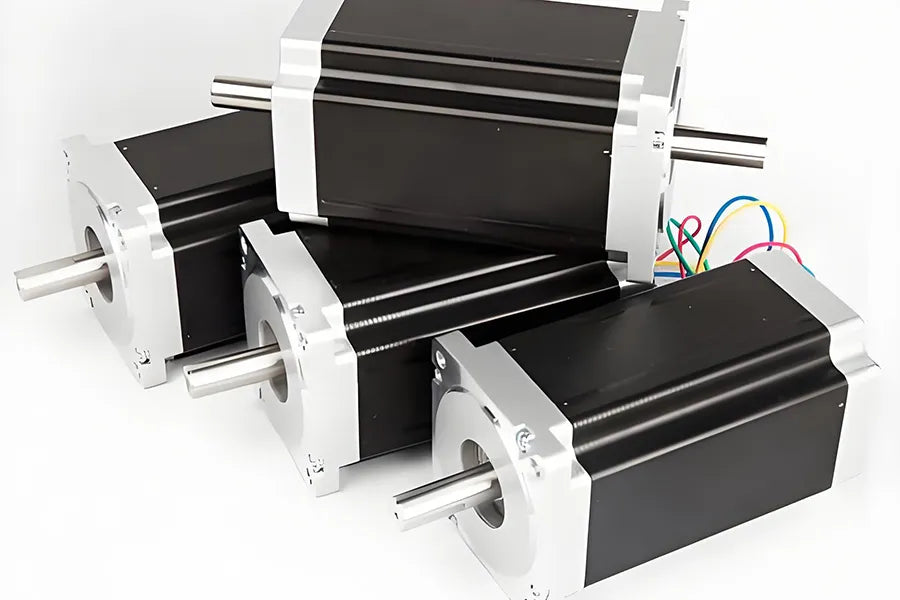

A dual axis stepper motor essentially integrates two output shafts into a single motor structure. Its basic electromagnetic principle is similar to that of a single-axis stepper motor, converting electrical pulse signals into angular or linear displacement based on electromagnetic induction.

A single motor driver transfers the processed pulse signals to two stepper motors, effectively driving two stepper motors with one driver. Many manufacturers choose dual axis drives for their significant cost savings and relative ease of operation. Their advantages are obvious.

2. Operating Principle

2.1 Pulse Signal Input

When an external controller inputs a pulse signal to a dual axis stepper motor, this pulse signal is distributed to the stator winding circuits associated with each axis. In a dual axis stepper motor, the stator windings corresponding to the two axes are typically electrically independent, but share the motor's main electromagnetic structure.

2.2 Magnetic Field Generation and Rotor Motion

-Pulsed current in the stator windings generates a magnetic field. Taking a common three-phase stepper motor as an example, applying power to the three-phase stator windings in a specific sequence creates a rotating magnetic field within the stator. For example, applying power in the order A-B-C-A... will cause the magnetic field to rotate in a specific direction.

2.3 Synchronous and Independent Control Characteristics of Dual Axes

In many cases, the two axes of a dual axis stepper motor can achieve synchronous motion. This is because they are exposed to the same motor's magnetic field. When the stator windings are energized to generate a magnetic field, the rotors of both axes rotate at the same step angle and speed (ideally).

3. Structural Components

The structure of a dual axis linear stepper motor typically includes:

The stepper motor body: responsible for receiving pulse signals and driving the transmission mechanism.

- Linear actuator: such as a lead screw, belt, rack, or linear guide, used to convert rotation into linear motion.

- Dual axis stages: Achieve linear motion in two directions, commonly found in XY stages or cross-guide systems.

- Drivers and controllers: Generate pulse signals to control the motor's direction, speed, and number of steps.

This combination allows the motor to easily perform two-dimensional positioning and can even be expanded to multi-axis control.

4. Applications of Dual Axis Linear Stepper Motors

Due to their high precision, low cost, and relatively simple structure, dual axis linear stepper motors are widely used in:

- 3D printers—Control the movement of the print head in the XY plane, achieving precise layer-by-layer printing.

- CNC numerical control equipment—Used for two-dimensional processing such as small engraving machines, laser cutting machines, and plotters.

- Automated production lines—Perform two-dimensional displacement in assembly, testing, and handling.

- Robotic systems—Provide planar movement or gripping positioning for end effectors.

- Medical equipment—Precisely move probes, syringes, or testing platforms.

- Optical and laboratory instruments—Control the translation of sample stages to achieve high-precision positioning.

5. Advantages of Dual Axis Linear Stepper Motors

Compared to traditional motor drive systems, dual axis linear stepper motors offer the following advantages:

- Precise positioning: The step distance of a stepper motor is controllable, enabling micron-level linear positioning.

- Compact structure: The integrated XY stage takes up less space than two separate motor-mounted mechanisms.

- Low cost: Compared to servo motors or linear motors, it offers a more cost-effective solution.

- Simple control: Utilizing pulse control, it can be operated with common controllers.

- High flexibility: Open-loop or closed-loop control can be selected based on requirements.

Summary

Dual axis linear stepper motors are motion systems that combine a stepper motor with a linear drive mechanism, enabling precise control in both the X and Y directions. Due to their high positioning accuracy, low cost, and compact structure, they have become important actuators in industries such as 3D printing, CNC equipment, automated manufacturing, robotics, and medical treatment. If you are interested in our products, please contact us!